Corrosion, a natural process causing metal degradation, poses significant challenges in automotive collision repair, complicating repairs and compromising structural integrity. Adopting advanced anti-corrosion materials is crucial for mitigating these issues. These solutions include high-performance coatings that ward off moisture and contaminants, as well as innovative alloys offering superior resistance to corrosion. Integrating these anti-corrosion materials into vehicle repair processes enables shops to deliver OEM-quality repairs, ensuring customer satisfaction and maintaining long-lasting vehicle durability.

In the realm of manufacturing and automotive repairs, corrosion stands as a relentless foe, compromising integrity and quality. To counter this challenge, understanding and adopting effective anti-corrosion materials is paramount for ensuring seamless OEM-quality repairs. This article delves into the heart of corrosion’s impact on original equipment manufacturer (OEM) processes, explores diverse anti-corrosion material options, and highlights strategies for implementing them to revolutionize repair techniques.

- Understanding Corrosion and Its Impact on OEM Repairs

- Exploring Anti-Corrosion Materials: Types and Benefits

- Implementing Seamless OEM-Quality Repairs with Anti-Corrosion Solutions

Understanding Corrosion and Its Impact on OEM Repairs

Corrosion is a natural process that occurs when metals interact with elements like water and oxygen, leading to degradation and strength loss over time. In the context of OEM (Original Equipment Manufacturer) repairs, especially in automotive collision repair, understanding corrosion is paramount. It not only affects the structural integrity of vehicle parts but also poses challenges during car paint services and fender repair processes. Corroded surfaces often require more intensive treatments and can result in less-than-perfect finishes when not managed properly.

The impact of corrosion on OEM repairs is significant, leading to weaker joints, reduced lifespan of replacement parts, and potential safety hazards. Therefore, adopting anti-corrosion materials is crucial for ensuring the longevity and reliability of vehicle repairs. By selecting appropriate substances that offer superior resistance to rust and degradation, professionals in automotive collision repair can deliver seamless, high-quality results, restoring vehicles to their original OEM standards.

Exploring Anti-Corrosion Materials: Types and Benefits

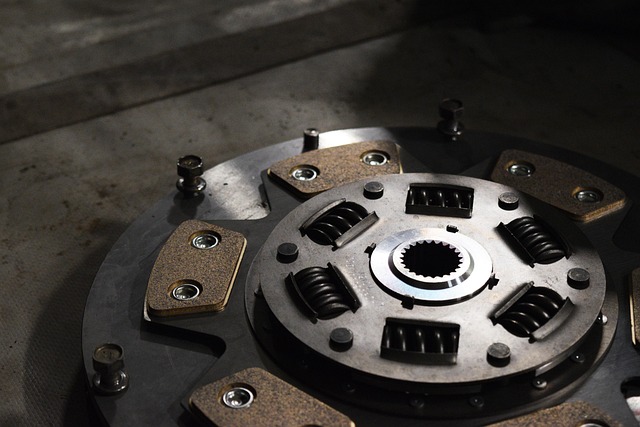

Exploring Anti-Corrosion Materials offers a world of benefits for those involved in car repair and vehicle maintenance. These specialized materials play a pivotal role in safeguarding against the relentless impact of rust and corrosion, which can significantly compromise the integrity of car bodywork services. From protective coatings to innovative alloys, various anti-corrosion solutions are now available, ensuring superior durability and longevity for vehicle bodywork.

Each type of anti-corrosion material comes with unique advantages, catering to diverse needs in both car repair services and OEM manufacturing. For instance, high-performance coatings provide an effective barrier against moisture and environmental contaminants, while specialized alloys offer enhanced resistance to corrosion, making them ideal for demanding automotive applications. By integrating these materials into their processes, repair shops can deliver top-quality, seamless repairs that match the original equipment manufacturer’s (OEM) standards, ultimately ensuring customer satisfaction and vehicle reliability.

Implementing Seamless OEM-Quality Repairs with Anti-Corrosion Solutions

Implementing seamless OEM-quality repairs with anti-corrosion solutions is a game-changer for vehicle body shops and collision centers. By utilizing advanced anti-corrosion materials, auto repair services can ensure long-lasting durability and restore vehicles to their original factory specifications. These innovative solutions protect against rust and corrosion, which are common issues after accidents or normal wear and tear, thereby enhancing the overall quality of repairs.

Anti-corrosion materials play a crucial role in maintaining the structural integrity of vehicles. When integrated into the repair process, they create a seamless bond with original equipment manufacturer (OEM) parts, ensuring a perfect fit and finish. This not only improves the aesthetic appeal but also guarantees enhanced safety features, as well as optimal performance for many years to come.

Anti-corrosion materials are transforming the way we approach OEM repairs, offering durable and seamless solutions that mitigate corrosion’s detrimental effects. By understanding the impact of corrosion and exploring the diverse types of anti-corrosion materials available, professionals can implement effective repair strategies. These advanced materials not only enhance the longevity of repaired components but also ensure they meet OEM standards, ultimately contributing to safer and more reliable vehicles.