Anti-corrosion materials are vital for protecting metal surfaces, extending lifespans in industries like vehicle repair and fleet maintenance. Proper preparation, including cleaning and surface treatments, ensures strong adhesion. Effective application techniques, meticulous surface prep, and using suitable tools enhance performance, prolonging structures' lives from cars to industrial equipment.

“Uncover expert training tips for mastering the application of anti-corrosion materials, essential for preserving structures against environmental damage. This comprehensive guide delves into the heart of these protective solutions, highlighting their role and benefits in mitigating corrosion. From preparation techniques to surface treatment and application methods, we explore best practices ensuring long-lasting protection. By understanding anti-corrosion materials, professionals can enhance durability, saving costs and preserving assets.”

- Understanding Anti-Corrosion Materials: Their Role and Benefits

- Preparation and Surface Treatment for Optimal Adhesion

- Application Techniques to Ensure Long-Lasting Protection

Understanding Anti-Corrosion Materials: Their Role and Benefits

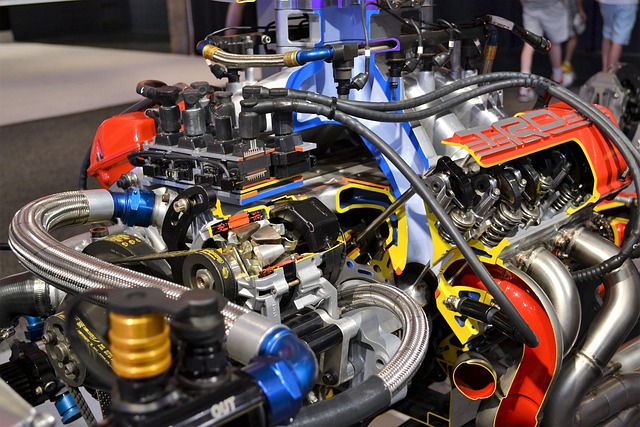

Anti-corrosion materials play a pivotal role in safeguarding various structures and components from the detrimental effects of rust and decay. These specialized substances are designed to create a protective barrier, preventing metal surfaces from oxidizing and deteriorating over time. By understanding their functionality and advantages, individuals involved in vehicle dent repair, fleet repair services, or auto body shop operations can ensure the longevity of vehicles and equipment.

The primary benefit of anti-corrosion materials lies in their ability to enhance the durability of metal surfaces. They form a protective layer, often characterized by its resilience and resistance to moisture and chemicals, thereby slowing down or even halting corrosion processes. This is particularly crucial for maintaining the structural integrity of vehicles and machinery, reducing maintenance costs and extending their service lives. In auto body shops, for instance, these materials are instrumental in ensuring that repaired vehicles withstand the test of time, retaining their aesthetic appeal and mechanical efficiency.

Preparation and Surface Treatment for Optimal Adhesion

Before applying any anti-corrosion materials, proper preparation and surface treatment are crucial for achieving optimal adhesion. This involves thoroughly cleaning the metal surface to remove any dirt, grease, or debris that could hinder the bonding process. A combination of mechanical and chemical methods can be employed, such as sanding, degreasing, and using specialized cleaning solutions. These steps ensure that the surface is free from contaminants, allowing for a stronger bond between the anti-corrosion coating and the metal.

Additionally, surface treatments like priming or etching can further enhance adhesion. Primers act as a bridge, improving compatibility between the metal and the anti-corrosion material. Etching, on the other hand, creates microscopic textures or pores on the surface, increasing its roughness and thus providing more anchor points for the coating. Such preparatory steps are vital not only in automotive body shop services for car collision repair and dent repair but also in any industrial setting where durable anti-corrosion materials are applied.

Application Techniques to Ensure Long-Lasting Protection

The proper application of anti-corrosion materials is key to ensuring long-lasting protection for any surface, be it on a car frame from collision damage repair or industrial equipment. Techniques such as spraying, brushing, and dipping should be executed with precision, adhering to manufacturer guidelines. For instance, when applying anti-corrosion coatings to metal surfaces in a collision repair shop, proper preparation is paramount. This involves cleaning the area thoroughly, removing any existing corrosion, and ensuring the surface is dry before application, which enhances adhesion and prevents premature wear.

Using the right tools and techniques for the specific anti-corrosion material also plays a significant role in its longevity. For car paint services or similar applications, using a spray gun equipped with the appropriate nozzle size and setting ensures even coating distribution. Proper surface preparation, coupled with meticulous application techniques, not only enhances the effectiveness of anti-corrosion materials but also extends the lifespan of the protected structure, whether it’s a car undergoing collision damage repair or any other metallic surface in industrial settings.

By understanding the role and benefits of anti-corrosion materials, properly preparing surfaces, and employing effective application techniques, you can ensure long-lasting protection for your structures. These strategies not only enhance the lifespan of metal components but also contribute to cost savings and environmental sustainability in today’s world. Incorporating these training tips into your workflow is a game-changer in navigating the realm of anti-corrosion materials.