Anti-corrosion materials are vital for industries aiming to combat metal degradation. These advanced compounds offer superior chemical resistance and durability, ensuring structural integrity and reducing maintenance costs in sectors like automotive repair. Strict industry standards mandate their use, with treatments like zinc coatings and epoxy finishes protecting metal surfaces from moisture and chemicals. Safe handling practices, including PPE and training, are crucial when working with these materials to minimize environmental impact and safeguard personnel health.

In industries where equipment longevity and safety are paramount, understanding anti-corrosion materials is key. This article delves into the essential role these materials play in preventing corrosion, a silent but costly enemy. We explore the unique properties and benefits of anti-corrosion coatings, offering a robust defense against environmental aggressors. Furthermore, we navigate industry safety standards, providing insights on compliance strategies to create safe work environments, ensuring peace of mind for workers and operations alike.

- Understanding Anti-Corrosion Materials: Properties and Benefits

- Industry Safety Standards for Corrosion Prevention

- Compliance Strategies: Ensuring Safe Work Environments

Understanding Anti-Corrosion Materials: Properties and Benefits

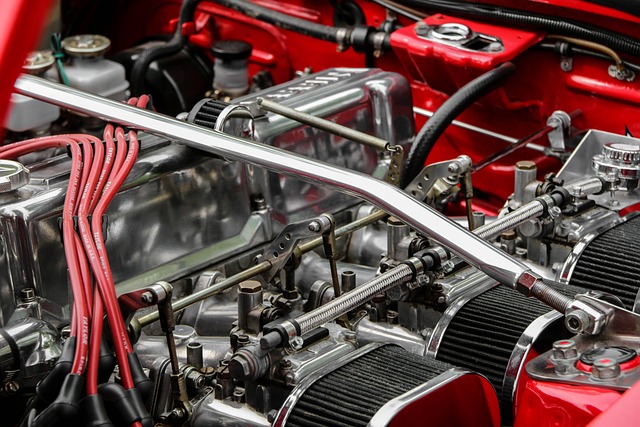

Anti-corrosion materials play a pivotal role in safeguarding various industries from the detrimental effects of rust and corrosion. These advanced compounds are designed to resist or prevent metal degradation, ensuring longevity and structural integrity. The primary benefit lies in their ability to protect critical components, infrastructure, and assets, thereby reducing maintenance costs and minimizing downtime in diverse sectors like automotive repair services, collision repair services, and industrial maintenance.

The key properties of effective anti-corrosion materials include excellent chemical resistance, superior durability, and the ability to form protective barriers on surfaces. Many modern formulations offer enhanced adhesion, flexibility, and resistance to environmental stressors, making them ideal for complex geometries and challenging conditions. In car bodywork services and collision repair, these materials are increasingly utilized to restore vehicles to their original state while ensuring long-lasting protection against future corrosion, thus enhancing safety and aesthetic appeal.

Industry Safety Standards for Corrosion Prevention

In today’s industrial landscape, ensuring the longevity and safety of structures is paramount, especially considering the devastating effects of corrosion. Industry safety standards have evolved to prioritize the use of anti-corrosion materials in various sectors. For instance, in automotive repairs, including fender repair, bumper repair, and collision repair services, professionals are increasingly relying on these materials to meet stringent safety compliance norms. The integration of anti-corrosion treatments not only enhances the durability of vehicles but also guarantees the structural integrity of vehicles during accidents.

These standards mandate the use of specific coatings, alloys, and finishes that deter corrosion formation. For metal surfaces, this may involve applying protective layers such as zinc or epoxy coatings, which act as a barrier against moisture and chemical attack. Such measures are crucial in industries where equipment is exposed to harsh environmental conditions, ultimately reducing maintenance costs and minimizing the risk of accidents caused by corroded parts, including those seen during fender repair or bumper repair processes.

Compliance Strategies: Ensuring Safe Work Environments

Compliance with safety standards is paramount when working with anti-corrosion materials, especially in industries like automotive repair. Professionals engaged in car body restoration or vehicle paint repair must adhere to strict protocols to safeguard against potential hazards associated with these substances. This involves implementing robust safety measures, such as using personal protective equipment (PPE), ensuring proper ventilation, and conducting regular training sessions for employees.

In the event of vehicle collision repair, where anti-corrosion coatings might be extensively used, compliance strategies must go beyond basic precautions. It’s crucial to have well-defined procedures in place for handling, storage, and disposal of these materials, minimizing environmental impact and protecting the health and safety of all personnel involved in the process.

Anti-corrosion materials play a vital role in enhancing industry safety compliance standards, preventing equipment failure, and ensuring secure work environments. By understanding the unique properties and benefits of these materials, companies can effectively navigate corrosion prevention strategies. Adhering to industry safety standards not only protects workers but also extends the lifespan of critical infrastructure, making it a crucial aspect of modern industrial practices.